2017

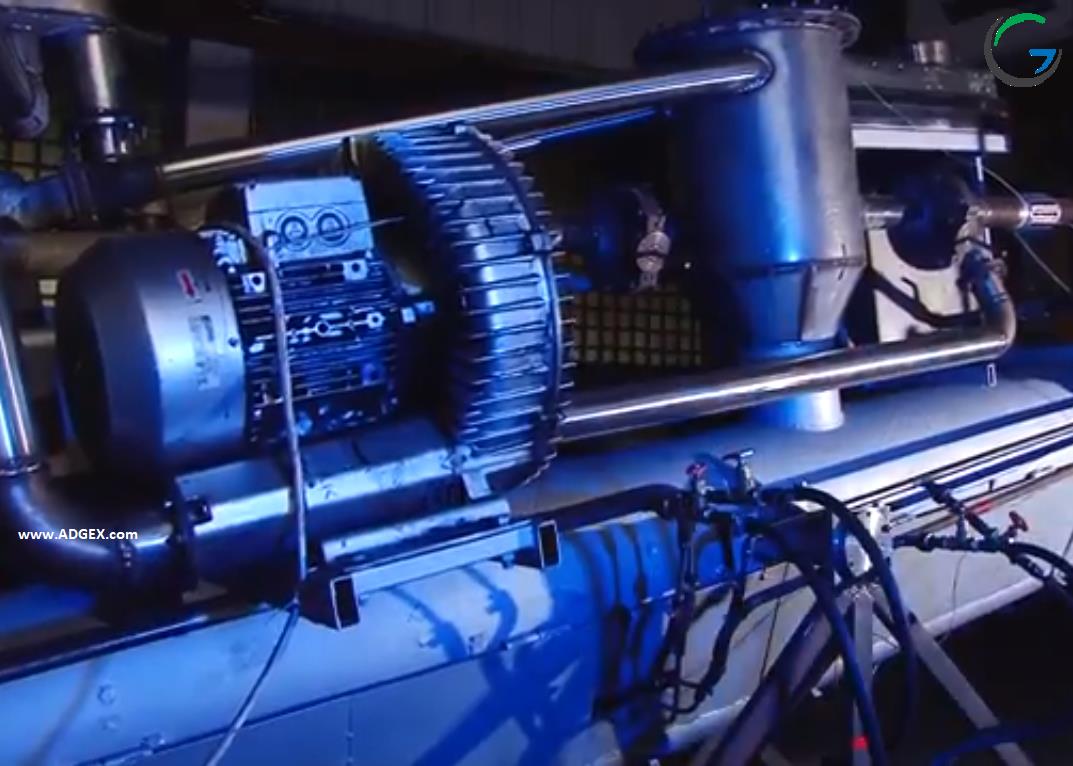

PRE-PRODUCTION PROTOTYPE OF THE GREENBLAZE MACHINE

As of today, the greenBLAZE processor has successfully passed the compulsory intermediate testing stage to check the unit’s steam generation system, the ignition system, the heating module of synthesis chamber, the screw feeder, the processors’ primary circuit and its hermeticity.

At the present stage, the greenBLAZE machine has been tested deliberately without using the electric energy generation unit. This allows us to run the reactor’s filling process with mixed feedstock and to reconfirm estimated volumes of the processor’s steam generation.

Homogenous feedstock was used as a starting test material. Afterwards our engineers and designers started loading mixed feedstock, which represented 4 altogether different sorts of carbon-contained materials in terms of fraction and humidity content. One of the unique features of the greenBLAZE Processor is its ability to regulate the rate of synthesis of consumed feedstock using a special mechanism, that varies the slope of the processor. This method was fully demonstrated within the tests. We are aware of no similar processors in the world so far.

The greenBLAZE machine is able to process different types of feedstock at the same time. Estimated volumes of steam production, required for generation of 1MW of electric energy were reached with a large margin.

Head of BLAZE Project Mr Alexander Rodin said:

“This particular plant can process practically all forms of solid waste. This includes for example construction waste, standard household garbage, which contains a large number of organic compounds. The processor releases virtually no dioxins as by-products, since the depth of processing is extremely high. Positive testing results and operational availability for service on national targeted markets allowed greenBLAZE to win the recognition of Australian and Russian governments.”

President of National Association of Operators of Waste Management Industry “RusRecycling” Dr. Elena Esina added:

“The greenBLAZE processor has a number of advantages against other similar technologies. The first feature is mobility. It can be mounted on all trucks or rail platforms and relocated to any region of the country. The second feature is universality. The machine is able to process all type of wastes, including such refractory materials as agroindustrial and medical wastes. So, when it comes to competitive advantages, these two major aspects bring greenBLAZE to the top level in waste treatment industry.

IN SEARCH OF EFFECTIVE SOLUTION TO SAVE THE PLANET

ADGEX PRESENTED ENERGYBRICK AND GREENBLAZE PROJECTS AS EFFECTIVE SOLUTIONS TO SOLVE GLOBAL ENVIRONMENTAL ISSUES