2016

WHEN ANY TRASH TURNS INTO CASH

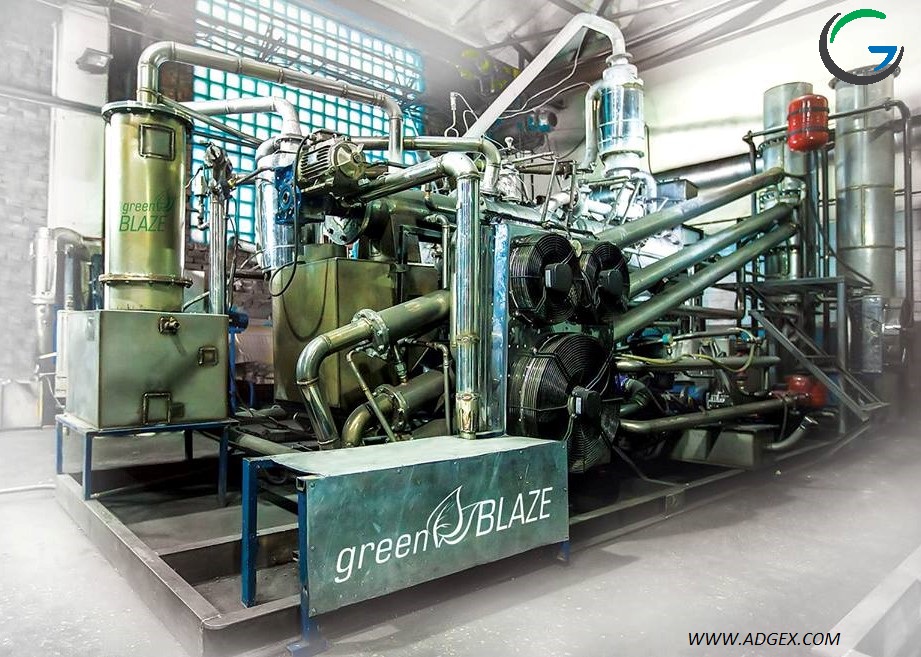

ADGEX officially announces that production of greenBLAZE processors for high-effective treatment of any carbonaceous wastes and materials has been launched. Primary purpose of these processors is treatment and utilization of MSW (Municipal Solid Wastes).

Waste utilization is a global-scale problem. Global economy has and will always produce wastes. There is no any optimal solution so far for safe and cost-effective utilization of MSW (Municipal solid waste). Landfilling, incineration and dumping of waste inflict irreparable harm on peoples’ health and environmental well-being, but existing treatment methods are not economically reasonable.

In accordance with the UN report, every year 200 billion tons of consumer wastes is produced. Uncontrolled landfills and improper utilization cause growth of oncology, infectious and lung diseases.

ADGEX BLAZE Division offers unique and mobile solution, capable of converting wastes into safe alternative energy sources, gaining matchless benefit and preserving natural resources of our Planet.

greenBLAZE is universal self-contained mobile multifunctional complex of closed cycle without open combustion, operating on the principle of high-temperature vacuum destruction.

ADVANTAGES OF greenBLAZE TECHNOLOGY

- greenBLAZE is a unique unparalleled technology of MSW treatment;

- greenBLAZE is a multifunctional processor. Depending on implementation type, Customer is able produce fuel, heat and electricity without any environmental harm and perilous emissions into atmosphere;

- greenBLAZE processor is mobile complex that can be dismantled at any time and relocated to another site;

- greenBLAZE has modular implementation that makes it possible to augment production volumes without heavy expenditures;

- Any implementation type of greenBLAZE processors requires wastes without special preliminary separation process, i.e. mixing of wastes is allowed without substantial costs;

- Implementation type of grenBLAZE for generation of synthetic liquid fuel allows Customer to produce various fuel grades, starting from high-octane synthetic petrol to diesel fuel. Moreover, to vary the fuel grade the only thing Customer needs to do is to change settings of the greenBLAZE processor.

Managing Director of ADGEX Ltd, Mr. Victor Uzlov said that at the present moment the Company has fully-serviceable processor with capacity of 50 liters of diesel fuel per hour. This processor has undergone more than 100 tests for the past two years. For this period the processor demonstrated high operability and durability level. It showcased survivability and high stability level even at excessive and destructive operational modes.

Then Mr. Uzlov added:

“One of the key market factors of greenBLAZE complexes is their ecological responsibility. Harmful emissions are virtually absent. At the same time greenBLAZE is a highly lucrative solution for almost any type of business that require waste treatment or independent production of electric energy and fuel.”

Application field of greenBLAZE modules is incredibly wide. This is treatment of MSW, coal, agriculture wastes, animal and poultry wastes and many other spheres.

ADGEX IS A STAND AWARD WINNER AT AUSRAIL PLUS 2015

ADGEX TAKES PART IN SEVERAL TOP-RANKED FORMAL EVENTS FACING FORTHCOMING GREENBLAZE RELEASE